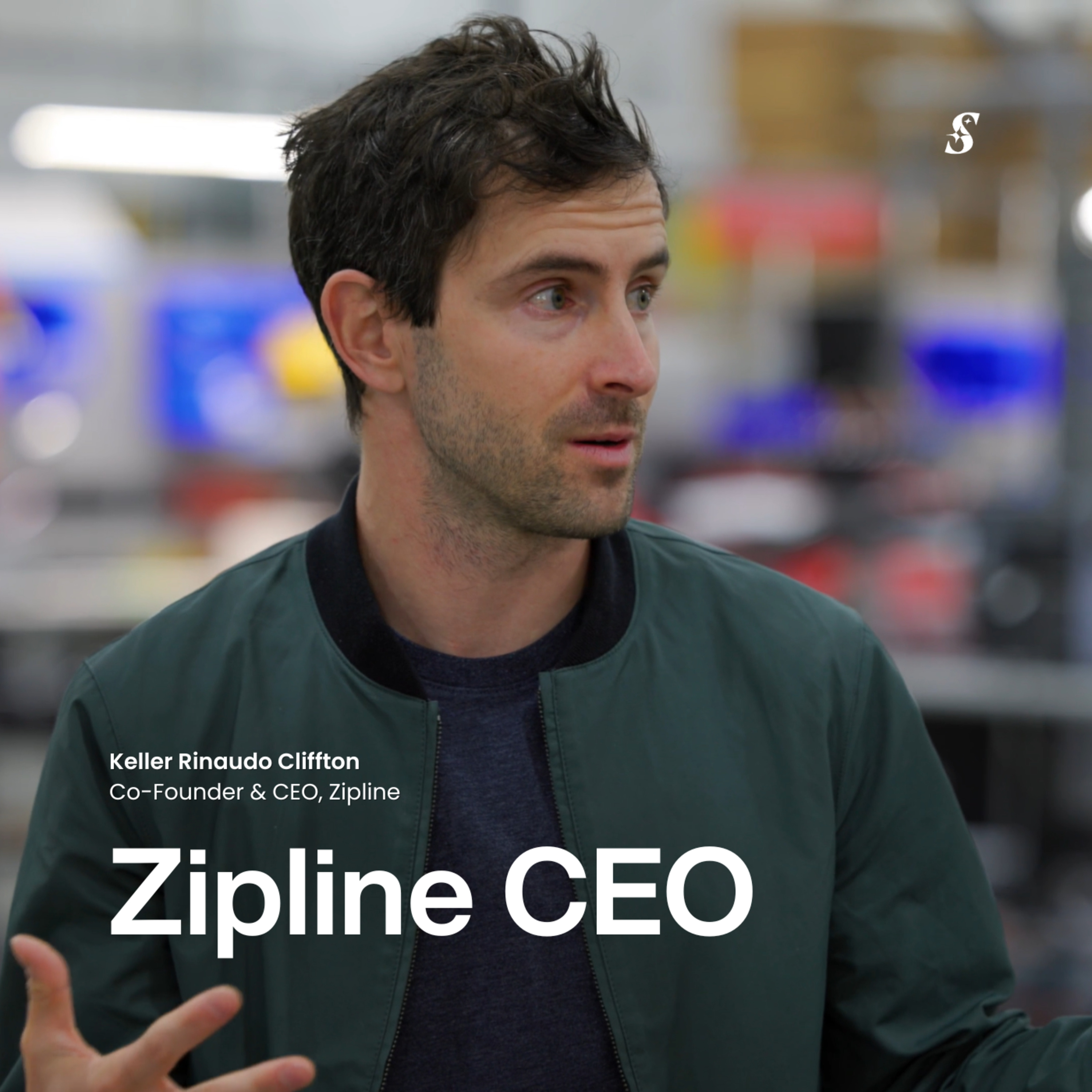

Zipline had to build its own components because the market only offered two extremes: cheap, unreliable consumer drone parts or prohibitively expensive military-grade systems. This "automotive grade" gap for reliable, cost-effective components forced them to vertically integrate to achieve their performance and cost goals.

Related Insights

Major US tech-industrial companies like SpaceX are forced to vertically integrate not as a strategic choice, but out of necessity. This reveals a critical national infrastructure gap: the absence of a multi-tiered ecosystem of specialized component suppliers that thrives in places like China.

Successful "American Dynamism" companies de-risk hardware development by initially using off-the-shelf commodity components. Their unique value comes from pairing this accessible hardware with sophisticated, proprietary software for AI, computer vision, and autonomy. This approach lowers capital intensity and accelerates time-to-market compared to traditional hardware manufacturing.

Creating the Dot delivery robot wasn't just a hardware challenge. DoorDash had to build the vehicle hardware, a custom L4 autonomy software stack, integrate them, and then plug the entire system into its complex logistics and merchant platform—a multi-year, first-principles effort.

The founders initially focused on building the autonomous aircraft. They soon realized the vehicle was only 15% of the problem's complexity. The real challenge was creating the entire logistics ecosystem around it, from inventory and fulfillment software to new procedures for rural hospitals.

The new wave of space startups is moving away from the SpaceX "build everything yourself" model. Instead, companies like Apex Space are unbundling the stack, specializing in one component like satellite buses. This allows for faster development cycles and creates a more robust, collaborative industry.

The push to build defense systems in America reveals that critical sub-components, like rocket motors or high-powered amplifiers, are no longer manufactured domestically at scale. This forces new defense companies to vertically integrate and build their own factories, essentially rebuilding parts of the industrial base themselves.

For D2C fashion brands, the inability of third-party suppliers to quickly fulfill reorders on trending products is a key trigger for vertical integration. Larroudé's co-founder realized the cost of one large factory order was equivalent to buying the machinery himself, enabling them to meet demand in weeks, not months.

Joby's business is extremely capital-intensive because they are vertically integrated 'down' to manufacturing components and 'up' to the customer-facing software. They strategically chose to go public early to secure the massive capital required to fund this full-stack approach, which includes commercial partnerships with Uber and Delta.

Boom Supersonic accelerates development by manufacturing its own parts. This shrinks the iteration cycle for a component like a turbine blade from 6-9 months (via an external supplier) to just 24 hours. This rapid feedback loop liberates engineers from "analysis paralysis" and allows them to move faster.

General-purpose robotics lacks standardized interfaces between hardware, data, and AI. This makes a full-stack, in-house approach essential because the definition of 'good' for each component is constantly co-evolving. Partnering is difficult when your standard of quality is a moving target.